How To Build A Movie Set Wall

How to Build a Wall Cabinet for DVDs

Updated: Jun. 19, 2022

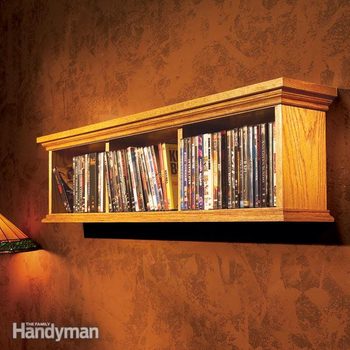

In i weekend morning you can build this wall cabinet for your DVDs.

Pull out your table saw and we'll evidence yous how to build a elementary, sturdy wall-mount chiffonier for your CDs and DVDs.

Yous might also like: TBD

Organize, organize, organize

Practice you take DVDs scattered all over the room? We offer this handsome cabinet as i solution to the clutter. As shown, the cabinet is 42 in. broad and holds about 60 DVD cases. Go ahead and aggrandize or compress the width to better concur your collection or to fit a particular spot on the wall. The construction techniques will be the same no thing the width. In this article, we'll bear witness y'all simple cut and joining techniques that'll deliver fine chiffonier-quality results. We'll evidence you lot how to make make clean and accurate crosscuts, rabbets (grooves on edges), and miters so you'll wind up with a spectacular finished product.

What you lot'll need

You don't need any special woodworking skills to consummate this projection, but y'all will need a table saw. To get good, true, splinter-free results, buy a forty-tooth carbide blade. If you have a pneumatic nailer, use it with 1-i/2-in. brads to fasten the cabinet parts and i-in. brads to nail the cornice. This will speed upwards the assembly and give meliorate results than hand nailing. All told, the bodily cutting and assembly only take a few hours, plus time spent finishing.

Cull the forest to match your decor

Our cabinet is made of oak and finished with oil stain (Minwax "Golden Oak") and shellac. Make your cabinet from any forest best matches your room'south decor. But be aware that if you choose wood other than poplar, oak or pino, the abode center probably won't stock matching molding for the top and bottom. If you cull paint for the finish, select poplar boards and clear pine molding.

Rip the parts to width start, and so to length

Begin by ripping the two 6-ft.-long ane×viii s to 6 in. wide, and so crosscut the stop and tiptop and bottom boards to length as nosotros show. Go alee and rip the divider panels to the final 5-in. width, but hold off on cut the dividers and top cap to length for now. Cutting those when you lot assemble the cabinet frame so you can measure and cutting for perfect fits.

Miter approximate tips and tricks

The cardinal to clean tight joints is to brand matching pairs of parts exactly the same length. We used our table saw, but you could use a miter box instead.

The minor debate that comes with your miter gauge isn't much good for belongings forest foursquare to make accurate cuts. Extend it past screwing a 24-in.-long argue extension to the miter gauge, with the right side hanging a bit by the blade (Photograph 1). (There are holes in the miter estimate only for this task.) One of the leftover pieces from your previous rips will work great for the extension fence. Cull screw lengths that penetrate the wood about 5/8in. after allowing for the miter gauge wall thickness.

Don't trust the angle indicators on your miter guess; they're bound to exist inaccurate. Instead, square the miter gauge to one of the miter guess slots with a carpenter's square (Photo one). When it'southward foursquare, tighten up the locking handle. Enhance the blade and cut off the finish of the argue and you're ready to crosscut. The end of the argue perfectly marks the saw blade's path. Line upwardly measurement marks with that finish and you'll know exactly where to place the lath for cutting.

Nest the wood against the miter gauge clear of the bract, start upwardly the saw, and push button the forest all the style by the blade. To be safe, shut off the saw earlier removing both parts.

Cut the rabbets

Now cut the 3 /8-in.-deep, 1/4-in.-broad rabbets on the back of the bottom, top and sides to create a recess for the i/four-in.-thick plywood back (Photo 2). First lower the blade below the throat plate and clench a straight iii/4-in.-thick sacrificial lath to the saw debate. Position the clamps at least an inch above the table so the 3/iv-in. boards can slide under them. Move the debate over the blade so information technology volition cut about 1/viii in. into the sacrificial board, then lock the fence, turn on the saw and slowly raise the bract into the board until information technology's about 1 in. above the table to cut a clearance slot (Photo two). Lower the bract to 3/viii in. above the table to start cutting the rabbets.

Nudge the debate about ane/16 in. away from the blade and brand cuts on all iv boards (Photo ii). Be sure to concord the boards tight to the fence and the tabular array for shine, complete cuts. And keep your hands well abroad from the bract, considering you have to remove the guard to brand this cut. Continue moving the fence in one/16-in. increments and making cuts until you approach the final ane/4-in. depth of the rabbet. And so check the depth with 1/4-in. plywood and make fine adjustments in the fence to brand a last cut. The plywood should fit affluent with the back edge of the board.

Leave the depth setting on the blade and use the miter gauge to cut the rabbets on the end panels. Set the fence to cut 3/4 in. wide (measured to the far edge of the bract). Make a series of cuts at each end (Photo 3). Button the wood completely through and stop the saw earlier pulling the miter estimate back. The more and the narrower passes you brand, the less you'll need to clean upward the saw kerfs later. Shine any saw marks with a sharp chisel for a cleaner-looking, tighter-plumbing equipment joint (Photo 4).

Sand all the surfaces to 120 grit for open-grain wood like oak, pino, ruddy and walnut. And sand to 220 grit for closed-grain woods similar maple and birch.

Stain before assembling

If you're staining, we recommend staining the parts at this point considering information technology'south tough to get into inside corners after you assemble the cabinet. For stronger glue joints, cover the surfaces of the rabbets with masking tape to go on stain off. Cutting the plywood dorsum about 1/2 in. larger than the opening, prefinish information technology at the same time and cut it to exact size later forth with the heart dividers.

This footstep will give you lot better finishing results, but it will add to the project completion fourth dimension because it means letting stains dry before assembly. If you're wild to complete the cabinet in i shop visit, go alee and gather it, then stain and finish information technology later on.

Get together the sides, dividers and back

Glue and nail each end console to the top and bottom boards. Iv 1-in. brads, ii at the top and two at the lesser, are plenty. Then clamp the assembly together to pull the joints tight (Photo 5). Check for square right away before the mucilage sets. You'll need clamps that are at least 5 ft. long for this. Use blocks to spread the pressure over the whole articulation. If one of the diagonal measurements is longer than the other, gently squeeze another clench across those corners to pull the frame foursquare.

If y'all don't have long clamps, just mucilage and clench the joints together with a few extra brads. (The joints might not be as tightly fit as clamped ones, just you can plug slim gaps with forest filler afterwards.) Measure and cut the back to fit, and then glue and nail it in place with i-in. brads spaced every 6 in. (Photo 6).

Save the dividers for concluding. Mensurate and cutting them to fit, then space them equally in the cabinet and nail them through the summit and lesser with 1-1/two-in. brads (Photograph seven). No mucilage is needed.

Add together the cove trim and meridian cap

Cut and install the cove molding starting at 1 stop, then the long front piece, and so the other end. To get perfect final lengths (Photo 9), cut 45-degree bevels on a curt slice of molding to use as a exam cake when y'all're plumbing fixtures and cutting. Use your miter gauge to cut the bevels. The technique is the same as crosscutting, only with the saw bract fix to 45 degrees (Photo 8). Leave three/16 in. of "reveal" (exposed cabinet border) for a nice look. Y'all can go with a wider or narrower reveal every bit long as it's consistent. Fasten the molding to the cabinet with glue and one-in. brads.

Center the peak cap on either side of the molding and flush with the dorsum, then mucilage and pin it to the molding with 1-one/2-in. brads (Photograph 10). Identify the brads advisedly over the thick part of the trim. It'due south easy to accidentally blow through the narrower, contoured front end.

Articulate-coat the cabinet with the finish of your selection. It's easier to apply smoothen coats of finish with a spray can than with a castor, especially when y'all're finishing the interior. We used three coats of shellac. Information technology dries quickly and then you tin can completely terminate (all three coats) in 1 mean solar day. It's also the least hazardous of all finishes. Practise your spraying in a dust-free room and you won't even have to sand between coats.

Hang information technology on the wall

With a 42-in. cabinet, y'all should be able to hang information technology with ii-1/two-in. screws driven through the back and into two studs. But if yous can merely find ane stud, utilize drywall anchors virtually the end farthest from the stud.

Additional Information

- Assembly Diagram

- Cut Diagram and Materials Listing

Required Tools for this Project

Have the necessary tools for this DIY project lined up earlier you start—y'all'll salve time and frustration.

In addition, y'all will need a foursquare, record measure, table saw, wood chisel, and woods glue.

Required Materials for this Project

Avoid last-minute shopping trips by having all your materials ready ahead of time. Here'southward a listing.

Additional Information

Originally Published: June 20, 2022

How To Build A Movie Set Wall,

Source: https://www.familyhandyman.com/project/how-to-build-a-wall-cabinet-for-dvds/

Posted by: cushinglichent.blogspot.com

0 Response to "How To Build A Movie Set Wall"

Post a Comment